The birth of Thermibel

The birth of Thermibel The idea of creating Thermibel was born in the mind of Mr Giancarlo PISTIS who, together with friends and family, started Thermibel in 1982. Designing electronic temperature probes (Pt100 and thermocouples) and distributing temperature-related equipment were the two core businesses of Thermibel for a long time, until the laboratory was added in 1995. Today, Thermibel is the leading Belgian manufacturer of temperature probes for industry.

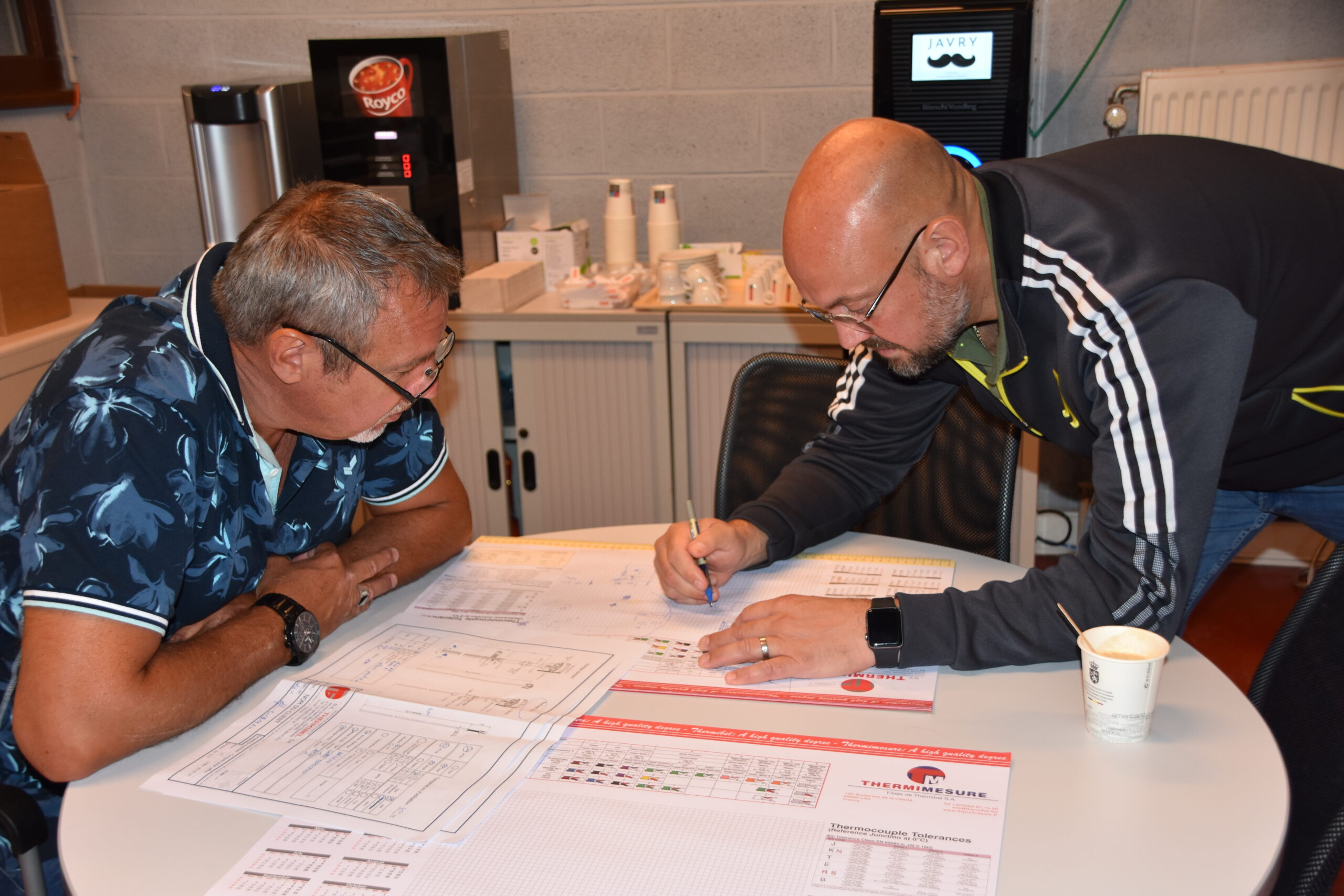

The know-how of our employees

A company is not just a factory with machines, it is above all a group of people working together to develop temperature solutions to meet your needs. Find out more about the members of the Thermibel family..

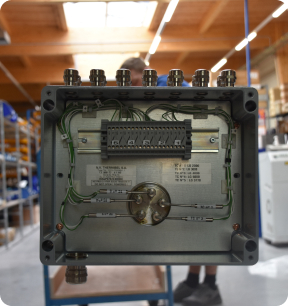

See our products