15 results

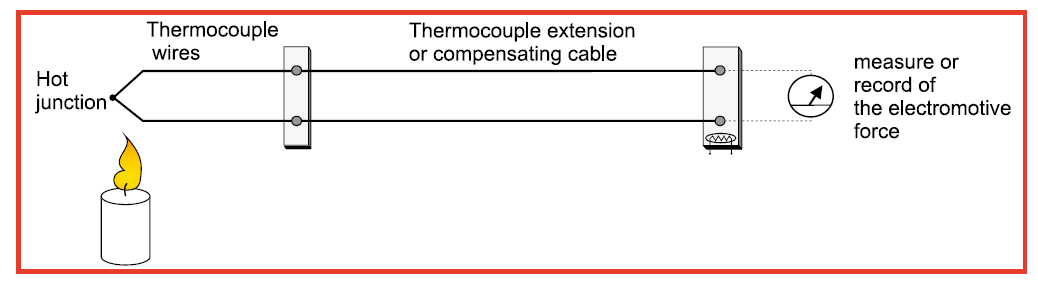

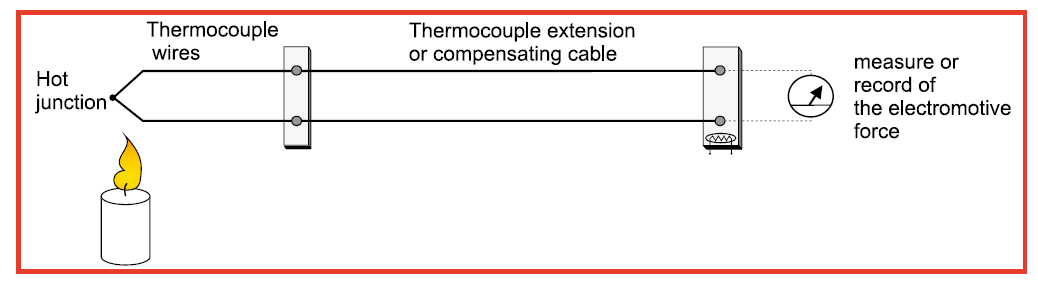

Suppose that we have to measure an oven temperature (800 °C) with a thermocouple and that the measuring equipment is located at a distance of dozens of meters from the measuring point. Usually a few meters are sufficient to bring the temperature down to 200 °C or less. From that point, in order to reduce the costs, it is possible to use either extension or compensating cable to connect the thermocouple to the measuring device.

Extension and compensating cables are used between open ends of the thermocouple and the reference junction in those installations where the conductors of the thermocouple are not directly connected to the reference junction.

The thermoelectric properties of extension and compensating cables shall be close to the properties of the corresponding thermocouple.

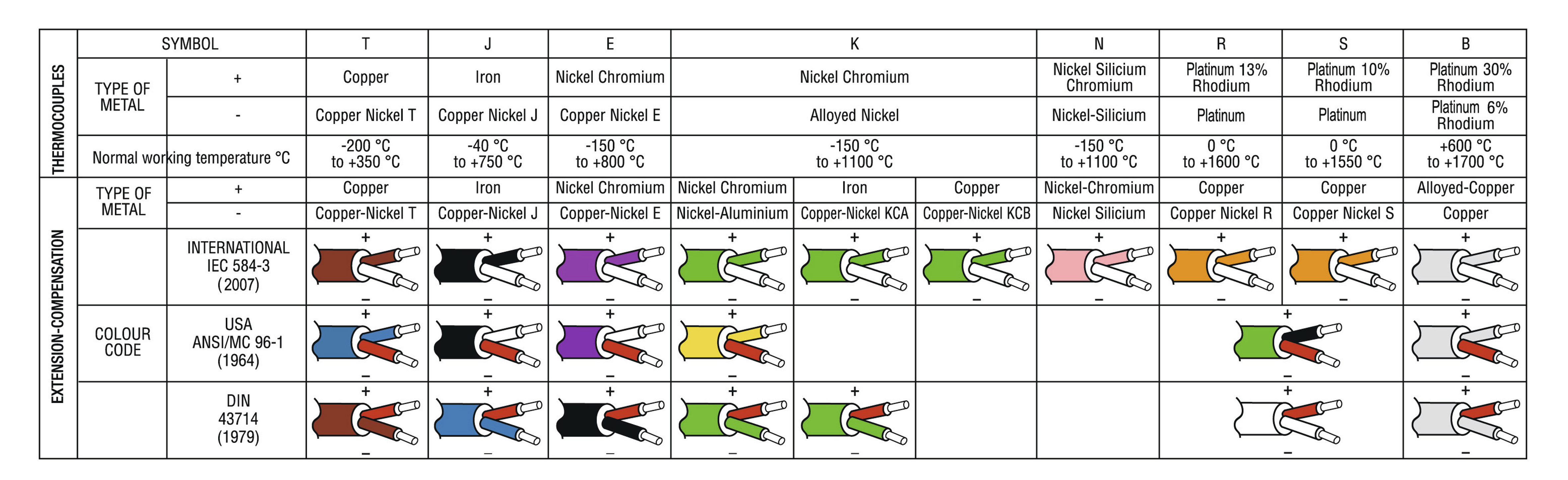

Extension cables are manufactured from conductors having the same nominal composition as those of the corresponding thermocouples. They are designated with the letter «X» preceded by the designation of the thermocouple, i.e. JX for thermocouple type J.

Compensating cables are manufactured from conductors having a composition different from that of the corresponding thermocouple. They are designated with the letter «C» preceded by the designation of the thermocouple, i.e. KC for thermocouple K. In some cases different tolerances apply for the same thermocouple type over different temperature ranges. They will then be identified with an additional letter such as A or B. For example, compensating cables for thermocouple K will be identified as KCA and KCB.

Extension and compensating cables are usually manufactured according to IEC 584-3 (EN60584-3) standards, but can also be made according to ANSI, UL or other standards upon request.

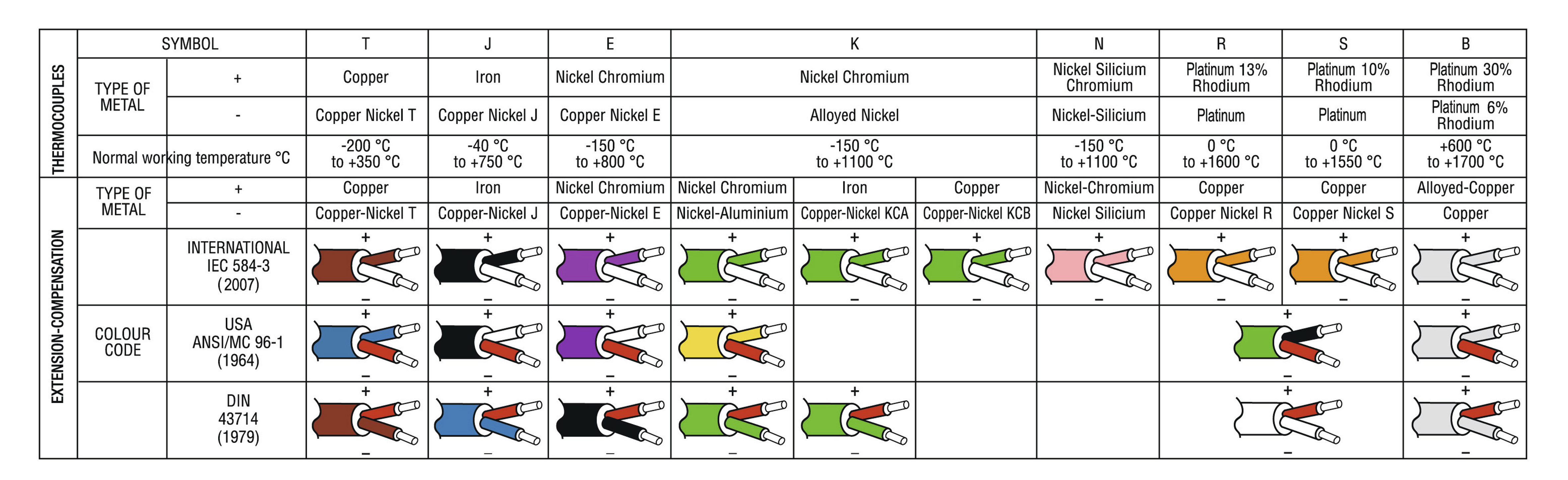

Colour identification of the most common thermocouple cables

Depending on the application and to suit particular environmental factors like temperature, humidity, physical integrity, the user can usually choose among several insulating materials.

- PVC (code PVC – short code P)

Polyvinyl Chloride is a thermoplastic resin with good resistance to water and aqueous saline solutions, acids and alkalis, moderate resistance to organic solvents and oils. PVC is a self extinguishing material. Generally usable between -30 and +105 °C. - Silicone rubber (code SIL – short code S)

Silicon rubber insulated cables show resistance to hot air up to 180-200°C. This material is not recommended for exposure to steam above 130°C. Do not use with alkalis, acids, liquid fuels, chlorinated hydrocarbons, esters, ketons and ethers, aromatic oils. Generally usable between -40 and +200 °C - Glass braid

Impregnated glass fibres type «E» (code TEX – short code E) usable to 400 °C or Impregnated glass fibres type «R» high temperature (code TRX – short code R), usable to 650 °C - Fluorinated resins

These resins exhibit outstanding chemical inertia, dielectric properties and heat resistance. Most common types are PTFE (short code F), PFA (short code A) and MFA (short code M). While PTFE has the highest melting point, other perfluorinated resins like PFA and MFA exhibit similar chemical resistance with slightly lower melting points but have the advantage to be easily extruded.PFA melts at 306 °C and can be used for continuous operation between -200 and +260 °C

MFA melts at 280 °C and can be used for continuous operation between -200 and +250 °C

Fire resistant cables: available upon request.

- Most common protections are :

- Braids: tinned copper (short code CS), steel (short code TA) and stainless steel (short code TI)

- Shields: aluminised polyester tape with drain wire (short code AL)

- Steel armour (short code AC)

- Cables with double braid or double shield (short code DX) can also be ordered upon request.

Thermocouple compensation and extension cables are also identified with their cross-sectional area in mm2 (3-digit short codes) which also indicates that the conductors are made of strands of thin wires to keep the cable flexible.

In case that solid conductors are required, the diameter will be mentioned (short codes starting with D and diameter in tenths of mm ex: D13 for Ø1,3 mm)

Remark: more detailed data sheets can be obtained upon request.

10 results

- PVC (code PVC – short code P)

Polyvinyl Chloride is a thermoplastic resin with good resistance to water and aqueous saline solutions, acids and alkalis, moderate resistance to organic solvents and oils. PVC is a self extinguishing material. Generally usable between -30 and +105 °C. - Silicone rubber (code SIL – short code S)

Silicon rubber insulate d cables show resistance to hot air up to 180-200°C. This material is not recommended for exposure to steam above 130°C. Do not use with alkalis, acids, liquid fuels, chlorinated hydrocarbons, esters, ketons and ethers, aromatic oils. Generally usable between -40 and +200 °C. - Glass braid

Impregnated glass fibres type «E» (code TEX – short code E) usable to 400 °C. - Fluorinated resins

These resins exhibit outstanding chemical inertia, dielectric properties and heat resistance. Most common types are PTFE (short code F), PFA (short code A) and MFA (short code M). While PTFE has the highest melting point, other perfluorinated resins like PFA and MFA exhibit similar chemical resistance with slightly lower melting points but have the advantage to be easily extruded.

– PFA melts at 306 °C and can be used for continuous operation between -200 and +260 °C

– MFA melts at 280 °C and can be used for continuous operation between -200 and +250 °C

Fire resistant cables: available upon request.

In both cases, the idea is to keep the resistance of the cable as small as possible to reduce the measurement error or to allow the transmitter to draw its maximum current in the case of 4-20 mA loops. Therefore, the cross section of the cable should be increased when the cable length increases.

- Braids: tinned copper (short code CS), steel (short code TA) and stainless steel (short code TI)

- Shields: aluminised polyester tape with drain wire (short code AL)

- Steel armour (short code AC)

- Cables with double braid or double shield (short code DX) can also be ordered upon request.

In case that solid conductors are required, the diameter will be mentioned (short codes starting with D and diameter in tenths of mm ex: D13 for Ø1,3 mm)

Remark: more detailed data sheets can be obtained upon request.

Colour code according to IE C751:

- Single temperature sensor: white/red

- Dual temperature sensor: white/red (sensor 1) yellow/black (sensor 2)

6 results

- Glass fibre braids

Impregnated glass fibres type «E» (code TEX – short code E) usable to 400 °C or Impregnated glass fibres type «R» high temperature (code TRX – short code R), usable to 650 °C - Ceramic fibre braids

Continuous filament ceramic fibres used for conductor and cable jacketing can withstand very high temperature while maintaining significant strength and flexibility up to 1200 °C for long periods. - Fluorinated resins

These resins exhibit outstanding chemical inertia, dielectric properties and heat resistance. Most common types are, PFA (short code A) and MFA (short code M). While PTFE has the highest melting point, other perfluorinated resins like PFA and MFA exhibit similar chemical resistance with slightly lower melting points but have the advantage to be easily extruded. - Fluorinated resins

These resins exhibit outstanding chemical inertia, dielectric properties and heat resistance. Most common types are PTFE (short code F), PFA (short code A) and MFA (short code M). While PTFE has the highest melting point, other perfluorinated resins like PFA and MFA exhibit similar chemical resistance with slightly lower melting points but have the advantage to be easily extruded.

PFA melts at 306 °C and can be used for continuous operation between -200 and +260 °C. MFA melts at 280 °C and can be used for continuous operation between -200 and +250 °C. - Kapton®

Kapton is a polymer developed by DuPont and exhibits superior performance to any other polymeric organic resin: -200 to +400 °C. These films do not melt and are fire resistant. PVC and silicone rubber insulated cables are usually not used due to their limited temperature range but they are available on special request.

Most thermocouple cables have an insulation around each conductor plus a second layer around the pair. If the application requires it, these cables can be obtained with a metallic overbraid as an option.

In the case that stranded conductors are required, the cross section will be mentioned

Remark: more detailed data sheets can be obtained upon request.

Colour identification of the most common thermocouple cables:

Thermocouples can be made from bare wires but need an electrical insulation. While one can use ceramic beads or mineral filled sheaths for high temperature, there exists a variety of application which only require a thin insulation medium to perform the measurement (furnace tests, laboratory tests, combustion tests, autoclave validation, freezers tests, etc.).

Therefore thermocouple cables exist in a variety of types and insulations.

The most common are fluorinated resins, Kapton®, glass fibres and ceramic fibres.